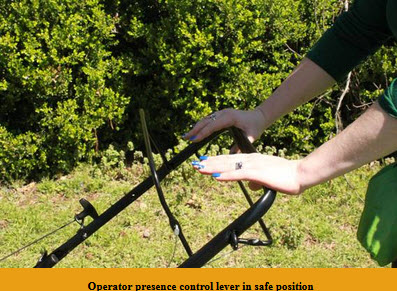

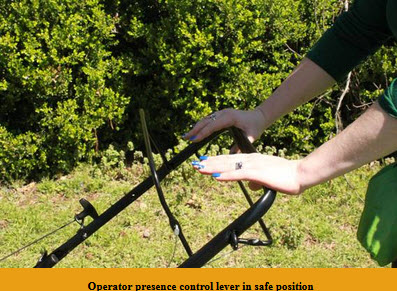

Lawnmowers cause over 50,000 emergency-room visits every year, based on NEISS data on consumer product injuries. These injuries are distributed evenly between ride-on and walk-behind style mowers. The necessary cutting action of a mower results in an inherent hazard, until technology is developed that can cut grass but not living tissue. While various safety advances over the years have reduced the amount of injuries, the extremely high number of accidents related to mowers that continue to occur show the need for further enhancement of product safety. Operator presence switches (OPS) are simple electric limit switches that ensure that the operator is in a safe operating position while the machine is operating. In walk-behind mowers, operator presence is verified by a spring-loaded hand lever that must first be gripped before the engine can be started. If the operator presence handle is released after the mower is started, the lever returns to the safe position, which stops the engine of the mower.

This ensures that the operator has his or her hands safely on the mower handle. Many accidents in the past were due to mower operators manually clearing the mower cutting area without first stopping the mower. Operator presence became required by a CPSC directive, which made the directive part of federal law (16 CFR 1205), requiring walk-behind mowers manufactured after June 30, 1982 to be equipped with operator presence technology. This requires that mowers have a continuous pressure device that stops the blade within 3 seconds after being released. There are additional requirements based on whether the mower has manual or automatic starting, and the location of the starting mechanism. Annual emergency room visits due to walk-behind mowers dropped from a high of 55,000 in 1985 to around 30,000 in 1993, likely due to the CPSC directive.

Riding mowers

Riding lawn mowers are not subject to the same regulations as walk-behind. While there is an ANSI B71.1 2003 safety standard covering riding lawn mowers which is recommended by the CPSC, compliance with this standard is voluntary. So while walk-behind mowers must have an effective operator presence system, it is not required on riding mowers. ANSI B71.1 does call for operator presence systems that will stop blade movement within 3 seconds, as well as no-mow-in-reverse (NMIR) that stops the blade if the mower is shifted into reverse. There are provisions for temporarily overriding the NMIR feature. While not mandatory, most manufacturers choose to comply with these safety features. The operator presences system of riding mowers is typically a spring-loaded limit switch placed underneath the mower seat.

When the operator is not in the seat, this switch is not engaged due to a simple helical spring that keeps the unloaded seat in a suspended position.

When the operator sits down, the seat-supporting spring is compressed, allowing the operator presence switch to be engaged.

Zero Turn Mowers

Zero-turning radius mowers have a similar operator presence system in the seat of the mowers. In addition, some manufacturers have control levers that act as a type of operator presence. Most zero-turning radius mowers use long arms that control hydraulic cylinders that are used to control mower movement. To start the mower, these arms typically have to be in the neutral lock position, which is the handles pushed outward away from the mower. This allows entry and exit to the mower. To move the mower, the arms are rotated inward. In order for the operator to leave the seat, he or she rotates the control levers to the side to allow easy exit.

Other Safety Devices

Roll over protective structures (ROPS) and a seatbelt are necessary to provide adequate operator protection while operating riding lawn mowers and zero-turning radius (ZTR) mowers. Many manufacturers are now offering ROPS on their ZTR models as either standard or optional equipment. Due to the sensitive nature of ZTR controls, as well as the quick response, and high speeds of these types of mowers, ROPS and a seatbelt are imperative. Traditional lawn tractor type riding mowers can benefit from a ROPS and a seatbelt as well, as many rollover accidents occur with these types of mowers. ROPS and a seatbelt are a proven combination to prevent deaths in overturning accidents.

Brakes for ZTR mowers are not standard equipment on many mowers, but provide additional security and emergency stopping power that are necessary to provide adequate safeguard systems. Due to the very extensive training and experience that most people have with automobiles, a similar control setup is recommended so correct action is taken in emergency responses.

When is a Mower Defective?

If a mower fails to provide the necessary safety features, it may cause unnecessary accidents. Mowers should adhere to the mandatory lawn mower safety regulations as well as voluntary safety standards. Failure to provide effective and lasting safety features is unacceptable. Some mower accidents may be the result of inadequate mower maintenance, or bypassing of safety systems. Give us a call at (855) 627-6273, or email us at johnlryan1@gmail.com, and let us help you with your mower accident case.

What We Can Do to Help

At Mechanical and Safety Engineering we have the experience to help you with your lawnmower accident case. We have extensive experience determining the cause of accidents and product failures, and differentiating between design defects, maintenance related accidents, and user error. We can help determine if there is a failure to maintain and whether there are any product design defects that may be implicated in the accident. Call us at (855) 627-6273 or email us at johnlryan1@gmail.com