1. ABSTRACT

Poor planning is a significant factor leading to project failure. If a project does not start right, it is unlikely that it will end right. Project management teams must be equipped and actively engaged with cost-effective tools to plan, monitor, control, document, and analyze changes to manage projects effectively. This is particularly true in a post-pandemic era when subject matter experts may be only remotely available to support project teams.

This paper summarizes the development and review steps of project plans and schedules during the front-end planning phases, including the critical phase of Front-End Engineering Design (FEED). The project milestones, resources, and completion dates established during FEED set the baseline control plan during project execution. Therefore, schedule optimization techniques, including using the DCMA 14-point schedule assessment and other quality checks, are recommended to validate that a project baseline is reasonably achievable. The tools and techniques presented here apply to all capital projects.

2. INTRODUCTION

Planning is more of an art than a science, particularly during the pre-project planning phase, when scheduling logic is more preferential than mandatory. There seems to be no right or wrong answer, as every project is unique, even compared to a similar project completed by the same company. The process of planning and scheduling a project is like a journey. It is important not only to meet goals but also to enjoy the trip. A scheduler is constantly challenged and rewarded along this journey. It feels good to finish a deadline—only to face another afterward. The journey may take one to new cities and continents as the project moves from one stage to another. This affects a project team and its dependents. People may need to relocate temporarily, face cultural challenges, meet new and interesting people, and ask loved ones to tolerate temporary family separation.

This paper provides a holistic guide for

capital project planning and scheduling. The methods and strategies used in this paper reflect practical optimization tools and techniques that have helped project managers and their teams think through entire projects in detail and build roadmaps to validate project schedules and milestones developed prior to the project execution phase. Best-in- class owners and contracting companies often use the modified version of the DCMA 14-point schedule quality checks summarized in this paper in front-end planning practices. The paper also capitalizes on best practices by prestigious industry benchmarking and construction research and industry organizations such as Independent Project Analysis (IPA), the Construction Industry Institute™ (CII), the Project Management Institute (PMI)®, and the Association for the Advancement of Cost Engineering, AACE International® (AACE). Most best-in-class companies or their project teams are sustaining members of these organizations. Many of them have adapted their in-house project management-related methods and procedures for managing front-end project planning.

3. SCHEDULING QUALITY ASSURANCE (QA)

Many project schedules are poorly prepared and require extensive re-baselining during project execution to become useful project management tools to correctly measure progress, determine the effect of changes in scope, and forecast the completion of contractual milestones and overall project completion dates.1 Poorly prepared schedules do not provide reliable tools to quantify and allocate responsibility for delays during project execution to provide a basis for a time extension or assess the need for acceleration to mitigate delays. This paper discusses procedures to rectify these common problems with project schedules, including ensuring that a schedule accurately reflects the complete contractual scope of work, evaluating schedule metrics to assess schedule integrity, reviewing schedule logic for reasonableness, evaluating reasonableness and completeness of the critical path, and comparing a schedule to the baseline or previous updates to identify significant changes.

A schedule quality assurance assessment provides valuable and comprehensive project schedule checks to ensure that: the complete scope of work is represented; schedule metrics are within industry norms; schedule logic is reasonable and competitive; and the project critical path is reasonable and achievable. Compiled findings from these examinations serve as a guide for schedule improvement.

4. SCHEDULE QUALITY CHECKS DURING THE PROJECT LIFE CYCLE

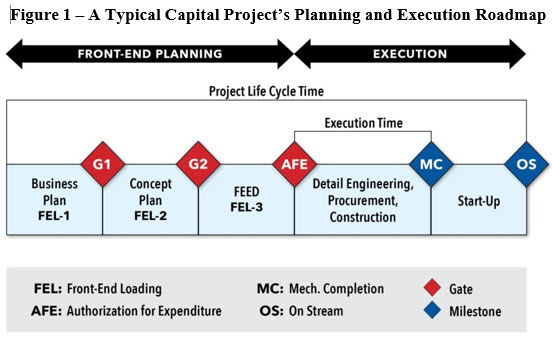

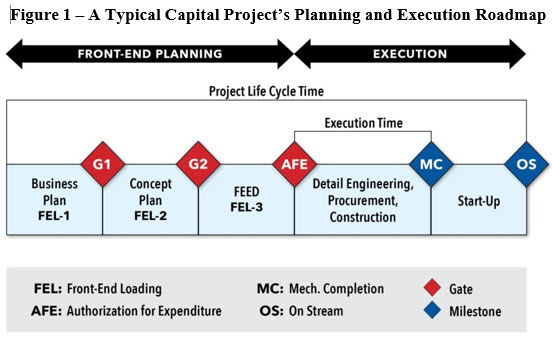

A project life cycle refers to the several phases and stages that a project passes through from initiation to completion. Major capital projects consist of two phases of pre-planning and execution. Each phase consists of stages marked by defined activities that correspond to project scope and deliverables. Approving the deliverables that are normally marked by a gated milestone manifests completion of each stage. Decision gates are critical checkpoints when phase deliverables receive formal review and approval, allowing a project to move to the next stage or phase. This includes the project’s financial approval with authorization for expenditure (AFE).

Figure 1 shows a typical capital project’s planning and execution roadmap showing the phases and stages of the project life cycle. Each stage has specific objectives, defined activities, deliverables, and decisions. Decision gates may be formal or informal, depending on the organization. The stages of the pre-planning phase are also referred to as Front-End Loading (FEL). IPA, a global consultancy in project evaluation and project system benchmarking, defines FEL as “the process by which a company develops a detailed definition of a project that was initiated to enable the company to meet its business objectives.”

2 IPA research has shown that project definition, or FEL, is one of the most significant drivers of project success. Edward Merrow, Founder and CEO of IPA, states that FEL is usually formatted into three stages:

3

- Business Case Development,

- Scope Development, and

- Front End Engineering Design (FEED)

At the end of the FEED phase, project funding is approved, and a project can move forward and be awarded for engineering, procurement, and construction (EPC) execution. The type of execution depends on the contracting strategies established during the pre-planning phase.

CII states that project planning is often synonymous with Front-End Planning (FEP) and FEL: “Project Planning is often synonymous with front end planning (FEP), front end engineering design (FEED), front end loading (FEL), pre-project planning (PPP), feasibility analysis, programming and conceptual planning.”4 The FEL process organizes the project life cycle into different phases, decision gates, or checkpoints to help management decide if a project is ready to continue to the next phase. According to CII, FEP is “the process of developing sufficient strategic information with which owners and contractors can address risk and decide to commit resources to maximize the chance for a successful project.”5 Well-performed FEP can reduce cost and project variability and increase chances of a project meeting its objectives. Front end planning is arguably the single most important process in the facility project life cycle.6

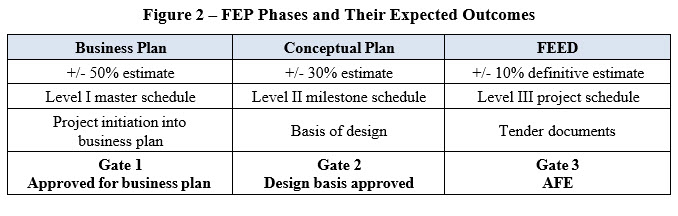

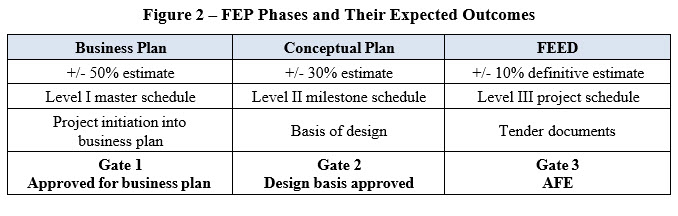

Figure 2 shows the three stages of FEP, cost/schedule deliverables, expected outcome, and decision gates at each stage. FEL presents an excellent opportunity to apply robust planning early in a project’s life cycle, when the ability to influence changes in design is relatively high and the cost to make those changes is relatively low. It typically applies to industries with highly capital- intensive projects with long life cycles.

The next section discusses recommended schedule quality checks at each stage of FEP. It is encouraged that schedule reviewers be included as part of gate reviews and score each of the checklists presented in the following few sections, marking “pass,” “fail,” or “need improvement” on the project schedule. If there are any failed items, the schedule should not be accepted until errors are corrected.

5. QUALITY CHECKS DURING BUSINESS PLAN DEVELOPMENT (FEL-1)

The business plan stage is often referred to as the project initiation stage. Figure 3 shows major activities and deliverables during the business plan stage.

Major activities include conducting a business case, preliminary conceptual studies, scope definition, stakeholders’ identification, and benchmarking against similar internal or external projects. Major deliverables include a project charter, project scoping paper, business plan schedule, Level I master schedule, and +/‒ 50% accuracy estimate. A business plan must include a preliminary description of the facilities planned to be built, defined in sufficient detail to develop a capital budget cost estimate, as well as a Level I master schedule...

Download PDF to continue reading article, footnotes, figures, tables, and references.