articles

Occupant Health Hinges On Indoor Air Quality

Originally published on FacilityExecutive.com, December 2020

By: Nancy M. McClellan, MPH, CIH, CHMM and Deborah Hetrick

Email: Ms. McClellan

Telephone: 224-517-2990

View Profile on Experts.com.

This year’s traditional cold and flu season is overshadowed by the ongoing COVID-19 pandemic. The virus continues to disrupt all aspects of life outside the home even as multiple vaccines appear to be on the horizon. Before people will return to offices, schools, malls, and other buildings in significant numbers, they need to feel confident that those indoor environments are healthy and safe. Healthy air plays a central role in making those safety calculations.

As our understanding of COVID-19 deepens with more research, we fully anticipate that the Centers for Disease Control and Prevention (CDC) will update its guidance between the writing of this article in mid-October 2020 and its publication date. Yet, this virus is far from the only factor at play in indoor air quality.

As our understanding of COVID-19 deepens with more research, we fully anticipate that the Centers for Disease Control and Prevention (CDC) will update its guidance between the writing of this article in mid-October 2020 and its publication date. Yet, this virus is far from the only factor at play in indoor air quality.

Mold, pollen, dust, smog, smoke, carbon dioxide, volatile organic compounds (VOCs), and other viruses and bacteria released through materials like furniture upholstery and carpeting, gaseous chemicals, particulates, and occupants, can all impact and

jeopardize human health. Investing in healthier indoor air now will lead to a better environment in your building as we emerge from this pandemic with occupants that are more productive and focused. And as health experts, business owners and consumers increasingly consider high quality indoor air as an imperative, incorporating protections into your standard operating procedures will support your building’s viability, value, and useful life over the long term.

A Holistic Approach

The first step toward improving indoor air is a whole-building assessment of facility risk factors including a pandemic. This is the best way to determine the facility’s most critical needs in light of indoor air quality. A professional, detailed analysis and report will also help you prioritize your response and give you the supporting documentation you may need to request additional resources from the C-suite.

Bear in mind that one size does not fit all and that a comprehensive approach is needed to make meaningful improvements in indoor air quality. A customized, multifaceted plan will enable you to address your building’s specific issues with the goal of reducing the overall risk. These efforts should not replace other safety measures like surface cleaning and disinfection and increased outside air volumes. Even state-of-the-art manufacturing facilities and labs adhere to rigorous cleaning protocols. The key is finding the right combination of technologies and procedures that align with your building’s requirements, and at the same time are feasible, efficient, and ultimately sustainable for your organization.

Fortunately, we benefit from the experience of specialized sectors like the healthcare, high tech manufacturing and pharmaceutical industries from which many of the best air-quality technologies have been adapted. At the same time, the marketplace has responded to COVID-19 with myriad products that make bold promises yet are ineffective, unnecessary, and, in some cases, potentially dangerous. Facility executives need to focus on methods and solutions that are, first and foremost, safe, effective, and proven, as backed by evidence.

Back To Basics

A healthy building is a well ventilated one. A pre-coronavirus study of sick buildings by the National Institute for Occupational Safety and Health, a division of the CDC, cited inadequate venting as the single biggest probable cause of Sick Building Syndrome. Bringing in 100% outdoor air is ideal if outside air conditions are satisfactory, but that’s not always achievable depending on the age and configuration of your HVAC system. If properly equipped, you can optimize ventilation and humidity controls, automate system operations to suit occupancy patterns, and adjust accordingly as seasons change.

Increasing the filtration should also be considered. All centralized HVAC system filters are rated according to a minimum efficiency reporting value (or MERV). Higher numbers mean more particulates are removed. The typical commercial system is designed and installed with MERV 6 or 8 filters. ASHRAE recommends MERV 13 or higher filers to help mitigate infectious aerosols. Systems capable of supporting highly efficient particle filtration (or HEPA) filters provide even more protection to building occupants.

However, these filters require greater air pressure and some HVAC systems may not have the capacity to accommodate these pressure loads. It is important to undertake a proper design review before making any changes. Testing and balancing considerations, as well as airflow patterns, should be factored in when making adjustments to optimize air quality.

Don’t discount the importance of old-fashioned preventative maintenance. Checking for leaks, changing filters, cleaning, and regular servicing go a long way toward supporting efficient filtering, extending the life of the system, and reducing energy consumption.

Specialized Technologies

Does your facility need more? In light of COVID-19, innovative ways to disinfect air and surfaces can be powerful tools in your regimen for a healthier, safer building. But even cutting-edge technology is useless if it is improperly installed, operated incorrectly, or is simply the wrong choice. Work with a trusted advisor or supplier who has the expertise to recommend systems that have been tested and vetted for occupant safety and their ability to inactivate viruses.

Does your facility need more? In light of COVID-19, innovative ways to disinfect air and surfaces can be powerful tools in your regimen for a healthier, safer building. But even cutting-edge technology is useless if it is improperly installed, operated incorrectly, or is simply the wrong choice. Work with a trusted advisor or supplier who has the expertise to recommend systems that have been tested and vetted for occupant safety and their ability to inactivate viruses.

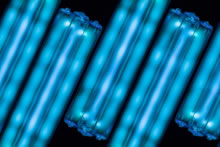

- Among the most recognized technologies for air and surface disinfection is ultra- violet (UV)-C light, which can inactivate harmful microorganisms. However, all the current applications require specialized training and installation as well as scrupulous attention to safety features, application procedures and controls. Improperly deployed, UV-C can cause damage to the outer surfaces of skin and eyes.

- Upper Room UV-C as an effective technology has the longest track record. Special fixtures irradiate the air at 7 feet or higher, so it can be safely used in occupied rooms. This technology has successfully controlled the spread of airborne pathogens in places like hospitals, prisons, and government buildings.

- Fixed-air handing unit UV-C directs a light fixture on HVAC drain pans, supply ducts, and cooling coils where pathogens may flourish. For the best outcome, pick a 360-degree application that also targets the recirculating air.

Installed UV lighting: Far UV is the latest innovation in this arena. It uses a 222-nanometer light source that is known to be safer for the skin and eyes, and similar to other UV-C options, applications need to incorporate important operational safeguards. This technology is especially promising for downlighting, but it requires critical knowledge of the room contents and occupancy patterns to effectively inactivate viruses.

A notable emerging technology is bipolar ionization, which relies on nature’s air-cleaning agents: electrically charged oxygen ions. When injected into indoor forced air via the HVAC system, these ions group fine particles into filterable clusters, breakdown harmful VOCs and inactivate microorganisms. They have demonstrated effectiveness on a broad range of airborne contaminants as well as unpleasant odors. Large industrial facilities and buildings located in areas where the outdoor air quality is poor are among the biggest users of this technology. Think of going inside an airport terminal and never smelling jet fuel. Some ionization techniques may create dangerous ozone particles, so it important to choose the technologies that have been vetted for occupant safety.

These are not the only options out there and more are in development and currently being vetted by the ABM Expert Advisory Council, composed of external leading experts in infectious disease and industrial hygiene. This group advises on many aspects of ABM’s business, including ABM’s proprietary EnhancedClean™ program.

Looking Ahead

Avoid assuming that newer technology is better. Focus on those technologies that complement your broader safety strategies and elevate your facility’s IAQ and overall health.

Just as 9/11 transformed security for all types of buildings beyond airport terminals, COVID-19 is redefining our idea of a safe indoor environment. The pandemic has heightened awareness of the role of building health even among those familiar with past challenges like norovirus, Legionnaire’s disease, and asbestos.

Most buildings can be turned into a safer, healthier place. But standards are changing and a new normal is emerging that we expect will have lasting implications for resilient facility management.

Citations

- EPA – VOC Impact on IAQ, November 6, 2017 https://www.epa.gov/indoor-air-quality-iaq/volatile-organic-compounds-impact- indoor-air-quality

- ABM Establishes Expert Advisory Council to Support COVID-19 Response and EnhancedClean™ Program, July 2, 2020 https://abm.gcs-web.com/node/25866/pdf

Nancy M. McClellan, MPH, CIH, CHMM, is is an award winning, Industrial Hygiene and Safety expert with over 25 years of broad international experience practicing, teaching and authoring to anticipate, recognize, evaluate, control and prevent workplace health and safety hazards in high hazard industries. She is domestically and internationally recognized for leadership service to the IH profession for the American Industrial Hygiene Association (AIHA), the American Board of Industrial Hygiene (ABIH), the Occupational Hygiene Training Association (OHTA) and the Joint Industrial Hygiene Ethics Education (JIHEEC) Boards of Directors and Committees. She currently serves on the AIHA Executive Board of Directors.

Deborah Hetrick is ABM’s senior vice president of Healthcare Technology Management and head of EnhancedFacility™. She can be reached at Deborah.hetrick@abm.com.

©Copyright - All Rights Reserved

DO NOT REPRODUCE WITHOUT WRITTEN PERMISSION BY AUTHOR.

Related articles

Follow us