7/14/2009· Accident Investigation & Reconstruction

There are approximately 180,000 lawnmower accidents per year. In this introductory presentation, we undertake to describe the various ways in which these accidents occur.

As Originally published by M.A.S.E. LLC, December/January 2008.

By: John Ryan

Tel: (855) 627-6273

Email Mr. Ryan

Material science is a broad field that has applications in numerous fields. In product injury cases, material science can help identify defects, determine causes of accidents, determine failure modes, and identify inconsistent manufacturing processes.

Product liability cases can often involve a product that has broken in some way. Ladder failures often result in lower ladder legs that bend inward, spreader bars that buckle. Vehicle accidents can result in broken control arm members, struts, and other structural members. Traffic accident forces can cause seatbelt and component failures. A basic understanding of material science will provide valuable background information on these types of cases.

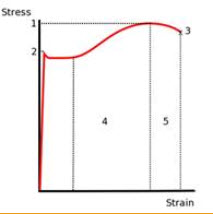

Several important characteristics are important to understand. The yield strength of a material is the stress (pounds per square inch) after which the material will begin to deform permanently. This permanent deformation is termed plastic deformation. The following diagram shows the relationship between stress and strain. Stress is what occurs when a force is applied to an object, it is simply the amount of force divided by the cross-sectional area of the material. Strain is the amount of deflection of a material. Stress-strain diagrams allow engineers to determine the performance characteristics of different materials. On the below diagram, point #2 represents the yield strength. Any stresses below this point will only result in temporary deformation and no material failure-the material will return to its original shape when the load is removed.

This isn't to say that when a material begins to bend or deform that it has reached its yield strength. Some materials exhibit extensive temporary yielding. Temporary bending or yielding (referred to as elastic deformation) occurs when a load is applied to an object that causes deformation of that object, but when the load is released, the object returns to its original shape.

When the stress is increased beyond its yield strength, also called the elastic limit, the material will continue to deform. The ultimate strength is the highest stress that a material can withstand without complete failure, however some materials do not fail at the ultimate strength. Point #1 represents the ultimate strength. Materials with a stress-strain curve as indicated in the diagram will continue to deform until a point on the stress-strain diagram is reached that indicates the combination of deformation and stress that results in absolute failure. This is point #3 on the diagram, and is known as the rupture or breaking strength.

Often the first sign of a potentially defective material is the pattern of failure that the material exhibits. The following are the basic modes of metal failure.

Fatigue Failures

Fatigue failures occur when an improperly selected material experiences fluctuating loads. Repeated loading of an inadequately strong material can result in fatigue cracks in high stress areas.

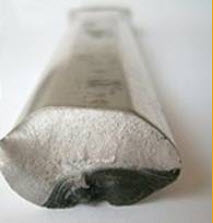

In the above photo, the fracture shows what a fatigue failure looks like. The dark colored metal is the area where the fatigue crack grew over time. After numerous cycles of loading, this fatigue crack grew until the object was weakened enough to fail catastrophically.

Corrosion Failures

Corrosion failure of a material is due to a chemical that has damaged the material. Stress corrosion failure is due to a material that is exposed to a corrosive environment and stress. This type of failure can occur well below normal rupture strengths and without any obvious signs of deterioration.

Ductile Material Failures

Ductile fractures are indicated by noticeable deformation of the material. Ductile fractures appear to be torn.

Brittle Material Failures

While ductile materials show extensive deformation prior to total failure, brittle failures usually occur with no plastic deformation of the material. A brittle failure can be due to an overload of a brittle material, and it can also occur when a part constructed out of ductile material is overloaded in a very short amount of time. High-force, low-time situations such as impact loading can cause a ductile material to exhibit a brittle-type failure. Knowing the circumstances surrounding the material failure can help an investigator determine why a material failed. Brittle fractures can also occur to a ductile material if changes have occurred to the material, such as embrittlement. Embrittlement occurs when a material loses its ductility, and can occur due to increasing or decreaseing temperatures, surface deformities, or a corrosive environment.

Embrittlement can also occur due to the treatment processes that occur when a metal part is created. Annealing is used to decrease brittleness of parts. While this decreases the strength of the material, it increases the ductility and toughness of the material. If not tempered correctly, though, temper enbrittlement can occur and cause catastrophic failures due to the lack of necessary ductility.

Creep

Creep occurs when a material deforms due to a constant stress and an elevated temperature. Stress rupture tests determine the amount of time until failure.

Material Science and Accident Reconstruction

Determining the cause of a failure can be a difficult task. The first step is identifying what type of metal failure occurred, as this allows an investigator to determine if the failure could be due to overloading of the part, corrosion, improper material selection, manufacturing defect, or some other cause such as a tempering process that changes the internal structure of the metal.

Examining the actual fracture plane will reveal some clues. A fracture plane that is at 45 degrees to the direction of loading is likely to be a ductile fracture. A brittle fracture is usually a fracture perpendicular to the direction of loading, with little deformation. A bending failure will often show some signs of bending deformation that occurred prior to failure.

The surface of the fractured faces will also reveal clues. Brittle fractures can be identified by their molecular fracture pattern. Electron microscope are often needed to determine what occurred on a molecular level, and determining this will aid in identifying the type of fracture that occurred. Ductile fractures will often have a dimpled fracture surface.

Determining the cause of material failure is essential to understanding the true nature of an accident that resulted from this failure. While many fractures occur due to being overloaded, sometimes fractures occur in a material that appears to be in good condition and operating in acceptable loading ranges. A failure analysis of the fractured material can reveal whether the manufacturer was responsible for some defect in the material, if the part was overloaded or under-designed, or if some change has occurred to the material.

John L. Ryan, BSME, P.E. is a Mechanical Engineer who provides general Mechanical and Structural Engineering expertise. Mechanical and Safety Engineering (MASE) provides full service analysis and accident reconstruction of products involved in accidents. Mr. Ryan's services have been requested for attorneys and insurance companies needing forensic engineering expert witness testimony to determine whether machinery and products involved in injury cases were adequately designed or whether they have a Design, Manufacturing, or Material Defect. All products are lab-tested on site to determine adherence to industry standards and engineering design protocol. Alternate preventative designs are developed when none exist commercially.

©Copyright - All Rights Reserved

DO NOT REPRODUCE WITHOUT WRITTEN PERMISSION BY AUTHOR.

7/14/2009· Accident Investigation & Reconstruction

There are approximately 180,000 lawnmower accidents per year. In this introductory presentation, we undertake to describe the various ways in which these accidents occur.

5/14/2009· Accident Investigation & Reconstruction

By: Shawn Gyorke

While the information recorded on event data recorders (EDRs), commonly referred to as vehicle black boxes, is tremendously helpful in determining how a traffic accident occurred and in improving safety, it was not until recently that EDR data was legally challenged in Illinois and ultimately accepted

7/31/2009· Accident Investigation & Reconstruction

Forensic Engineering Experts: Electrical Fires

Electric fires are becoming more common as appliances and electric feeds are used more and more in our daily lives. Like other fires, the root cause of an electric fire is the introduction of heat, oxygen, and fuel.