Introduction

Read Consulting was asked to determine why a welded chair failed and caused injury to the person sitting in it.

Description

The subject chair is made from a welded steel frame onto which a plastic seat is bolted (Figure #'s 1 & 2). It is typical of "stackable" chairs used in many institutions such as schools and community centers.

Results

The chair is constructed with two cross bars (tubular steel) on the front of the chair and one bar on the rear (Figure #2). These tubes hold the legs together in a rigid fashion. In addition, they support the plastic seat portion of the chair. The rear bar of the subject chair had separated from the legs (Figure #3). It is the separation of the rear bar that allowed user to fall backwards and onto the floor. Figure #3 shows the remainder of the legs of the subject chair. The two welds shown in Figures #'s 4 & 5 were those that held the rear bar. These are photos of the welds on the legs. Both welds are incomplete and poorly made. One side has only a tab of bonding; the other bonds only one fourth of the tube's circumference. A fatigue crack formed on the right leg weld and this eventually caused the weld to fail. Once the bar separated from the leg on the right side, the minimal weld on the left leg then failed and the user fell backward onto the floor.

Figure #1: Photograph of an exemplar chair showing what the subject chair looked like before the failure occurred.

Figure #2: Photograph of the underside of an exemplar chair. The bar that failed on the subject chair is indicated. It is the single bar that supports the back of the seat. If this bar fails the seat will become unstable and cause the user to fall backwards.

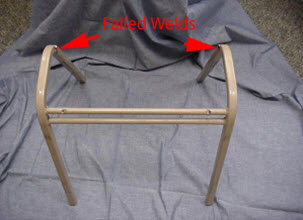

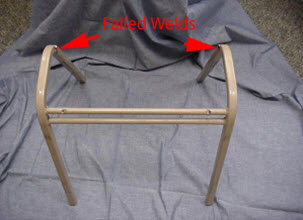

Figure #3: Photograph of the legs of the failed chair. One can see that the rear bar is missing.

I. Discussion: The cross bars were poorly welded to the chair legs. This type of weld is tricky due the thin wall of the tubing. This weld is best formed with two passes going completely around the circumference of the tube. On the first pass, the welder must be careful not to burn through the tube; therefore, his settings on the welding apparatus are critical. The second pass is to build up material around the first weld. This chair was welded with one pass that was very poorly executed. The weld didn't cover the entire circumference. For better support, it would have been better to have welded underneath the bar. Finally, both sides showed extremely poor penetration.

Figure #4: Photograph of what remains of the weld on the right leg of the subject chair. This is a fillet weld that shows good penetration only on the top 1/16th to 1/8th of the circumference of the pipe. The rest of the weld beads up and has no penetration (bonding) to the tube. The shiny part of the rest of the weld resulted from the tube scraping the paint off the weld bead when the failure occurred. The crack initiated as a fatigue crack that eventually failed in overload.

Figure #3: Photograph of what remains of the weld on the left leg of the subject chair. Toward the front of the chair, there is bonding on 1/4th of the tube circumference. The weld at the back outlines the tube, but it doesn't penetrate the tube. Here there is no bonding of the tube to the leg. One can see rust between the weld and the tube; this shows that water was able to penetrate this space; this is a further indication that the tube was not bonded to the leg in this region.

Dr. Thomas L. Read, CEO of Read Consulting received his PhD. from Stanford University in 1972. He has over 25 years of manufacturing experience in electronics, metallurgy, factory safety, failure analysis, glass fracture, glass failure and bottle failure. As a member of the electronics industry, Dr. Read has earned process patents and has an extensive background in manufacturing techniques. In parallel, he has spent over twenty five years as a consultant to attorneys and engineers in the areas of failure analysis, metallurgy, glass fracture, glass failure, bottle failure, factory safety, manufacturing problems, intellectual property and patent disputes.

©Copyright - All Rights Reserved

DO NOT REPRODUCE WITHOUT WRITTEN PERMISSION BY AUTHOR.