articles

Surface-Piercing Propellers

First published in Professional Boatbuilder magazine.

A paper with similar content was presented to the Northern California section of the Society of Naval Architects and Marine Engineers.

By: Mr. Paul Kamen

Surface Propulsion Analysis

Tel: (510) 540-7968

Email Mr. Paul Kamen

The art of positioning a propeller underneath a boat hull is not a new one. Designers and naval architects have been grappling with every aspect of the propulsion-by-propeller problem for generations, and the result has been the evolution of a well known set of standard and efficient solutions.

When a new and promising solution to a very old problem appears, it's usually made possible by advancements in some other related technology - material science or control and instrumentation devices, for example.

But in the case of surface-piercing propellers, there's really no new technology involved at all. Simply the re-arrangement of all the traditional elements of a propulsion system into a different configuration. A few features may be borrowed from the drive- line and hydraulics fields, but these technologies are also as old as the hills. The implication is that we've been wrong - or at least quite a distance away from optimum - for an awful long time. So it is with understandable skepticism that the idea of using surface-piercing propellers on more-or-less conventional small craft is greeted by the boatbuilding community.

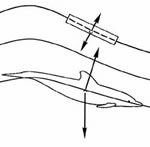

What is a surface-piercing propeller, anyway? Simply stated, a surface-piercing propeller (or surface propeller) is a propeller that is positioned so that when the vessel is underway the waterline passes right through the propeller's hub. This is usually accomplished by extending the propeller shaft out through the transom of the vessel, and locating the propeller some distance aft of the transom in the relatively flat water surface that flows out from the transom's bottom edge. (The exception being single-shaft catamarans, where the propeller hub intersects the undisturbed waterline.) In the case of articulated surface drive systems, the propeller shaft is driven through a double universal joint inside an oil-tight ball joint, allowing the shaft to rotate athwartships for steering and to trim up and down for control of propeller submergence. Fixed-shaft surface drives can use conventional shafts and stern tube bearings, but require rudders. In many racing applications, outboards and outdrives can be positioned sufficiently high on the vessel for the propellers to operate in a surface-piercing mode.

The important operating feature is that each propeller blade is out of the water for half of each revolution. And here is another reason for skepticism. Surely a propeller blade is more efficient if it operates continuously in the smoothest possible flow, rather than splashing through the water surface twice with each revolution. But nature can play tricks on our intuition. Sometimes an unsteady process is actually more efficient than its continuous counterpart.

Why use a surface propeller?

A summary of the principal reasons for the high performance of surface propeller systems relative to conventional installations follows.

Propeller Efficiency: Traditional propeller design and selection is almost always an exercise in trading off diameter against several other performance-limiting parameters. Basic momentum theory tells us that for a given speed and thrust, the larger the propeller, the higher the efficiency. While there are exceptions, most notably the effects of frictional resistance on large, slow-turning propellers, it is generally borne out in practice that a larger propeller with a sufficiently deep gear ratio will be more efficient than a small one.

A number of design considerations conspire to limit the maximum feasible propeller diameter to something considerably smaller than the optimal size. These include blade tip clearance from the hull, maximum vessel draft, shaft angle, and engine location. While this may at times make life easy for the designer - the propeller diameter specified is simply the maximum that fits - it can also result in a considerable sacrifice of propulsive efficiency. And if these geometric limits on propeller diameter are exceeded, the result can be excessive vibration and damage due to low tip clearances, or a steep shaft angle with severe loss of efficiency and additional parasitic drag, or deep navigational draft that restricts operation or requires a protective keel and its associated drag. In many cases, the best design solution is to live with a mix of all of the above problems to some degree.

The surface-piercing propeller frees the designer from these limitations. There is virtually no limit to the size of propeller that will work. The designer is able to use a much deeper reduction ratio, and a larger, lightly-loaded, and more efficient propeller.

Cavitation: When a submerged propeller blade cavitates, the pressure on part of the blade becomes so low that a near vacuum is formed. This happens more easily than one might think - atmospheric pressure is only 14.7 psi, not a very big number considering the size of a typical propeller and the thrust it is required to produce. If the suction on the low-pressure side of the propeller blade dips below ambient pressure - atmospheric plus hydrostatic head - then a vacuum cavity forms. (To be strictly correct, there is water vapor in the cavity, and the pressure is not a true vacuum, but equal to the vapor pressure of the water.)

When these vacuum cavities collapse, water impacts on the blade surface with a local pressure singularity - that is, a point with theoretically infinite velocity and pressure. The effect can approximate that of hitting the blade with a hammer on each revolution. Cavitation is a major source of propeller damage, vibration, noise, and loss of performance. And although high- speed propellers are often designed to operate in a fully- cavitating (supercavitating) mode, problems associated with cavitation are frequently a limiting factor in propeller design and selection.

The surface propeller effectively eliminates cavitation by replacing it with ventilation. With each stroke, the propeller blade brings a bubble of air into what would otherwise be the vacuum cavity region. The water ram effect that occurs when a vacuum cavity collapses is suppressed, because the air entrained in the cavity compresses as the cavity shrinks in size. Although the flow over a superventilating propeller blade bears a superficial resemblance to that over a supercavitating blade, most of the vibration, surface erosion, and underwater noise are absent.

In theory there is a slight performance penalty for allowing surface air into the low-pressure cavities. Instead of near-zero pressure on the forward side of the blades, now there is 14.7 psi pushing backwards. But in practice, this effect is not significant considering the total thrust pressures involved in high-speed propellers.

Note that cavitation can also be associated with sudden loss of thrust and high propeller slip, often caused by a sharp maneuver or resistance increase. This can still occur with surface propellers, although the propeller is ventilating rather than cavitating and the result is not as damaging.

Appendage Drag: Exposed shafts, struts, and propeller hubs all contribute to parasitic drag. Inclined the exposed shafts not only produces form and frictional drag, but there is also induced drag associated with the magnus-effect lift caused by their rotation. There is a surprising amount of power loss resulting from the friction of the shaft rotating in the water flow. In fact, for conventional installations a net performance increase can often be realized by enclosing submerged shafts in non- rotating shrouds, despite the increase in diameter.

Surface propellers virtually eliminate drag from all of these sources, as the only surfaces to contact the water are the propeller blades and a skeg or rudder.

Variable Geometry: When a surface propeller is used in conjunction with an articulated drive system, the vessel operator then has the ability to adjust propeller submergence underway. This has roughly the same effect as varying the diameter of a fully submerged propeller, and allows for considerable tolerance in selecting propellers - or it allows one propeller to match a range of vessel operating conditions. This capability is somewhat analogous to adjusting pitch on a controllable pitch propeller.

When the articulated drive is used for steering, the result can be exceptionally good high-speed maneuvering characteristics. On single-shaft applications, drive steering can also be used to compensate for propeller-induced side force, without resorting to an excessively large rudder or skeg.

Shallow Draft: This is the characteristic that motivates many designers to investigate surface propeller propulsion in the first place. The vessel's navigational draft can be as low as half a propeller diameter. Compared with other options for shallow water propulsion - most notably waterjets - surface propellers enjoy a very significant efficiency avantage. This advantage is most dramatic for low-speed applications, but is still present throughout the performance spectrum.

In the case of articulated drives, the propellers can be trimmed up until just the tips are submerged for intermittent operation in very shallow water, including beaching. Sometimes the design allows the propellers to trim sufficiently above the baseline so that the vessel can "dry out" with the props well clear of the bottom.

These are the intrinsic performance advantages of surface propellers. Other desirable characteristics include flexibility in machinery arrangement, ease of maintenance and repair, and simplified installation. In some applications involving hybrid propulsion systems, such as the combination of diesel cruise engines with a gas turbine sprint engine, the ability to retract one set of propellers completely clear of the water when not in use is an overriding consideration.

Selecting a Surface Propulsion System:

Having elected to investigate the surface propulsion option, the builder or designer is faced with a series of major decisions and a very limited amount of reliable data. First is the issue of fixed versus articulated. As outlined above, articulated drives have the advantage of variable propeller submergence, superior maneuverability, and extreme shallow draft capabilities. Fixed systems, on the other hand, do not require the hydraulic cylinders and associated pumps, control devices, and high pressure plumbing. Furthermore, fixed systems are often designed to work with conventional solid shafts and stern tubes, rather than the more complex universal-joint drivelines found in articulated systems. It should also be noted that articulated surface drives should not be relied upon to control vessel trim angle. Trimming the drive up and down will have only a small effect on vessel running trim, and separate trim tabs or other devices may still be desirable.

Very frequently, the nature of the vessel or operating conditions will dictate the fixed/articulated decision. Some multihulls, for example, have very narrow transoms that practically rule out an articulated system unless some alternative attachment points for the hydraulic steering and trim cylinders can be found. But in cases where variable trim is required for shallow draft or propeller retraction, a fixed system is clearly not viable.

In most cases, both the fixed and articulated options can be made to work, and the maximum performance possible with each should be comparable (although there have been applications in which variation of propeller submergence is necessary to pass through certain transitional speeds). Personal preference, relationship and proximity to dealers and distributors, and the existence of successful vessels with similar propulsion systems will probably govern this choice.

At this level, it is important to establish a relationship with the surface drive dealer or manufacturer's representative. For fixed surface drives, the Levi Drive Unit is the most popular worldwide. This system is distinctive for its inverted U-shaped rudder that encloses the propeller. A handful of other fixed drive manufactures compete in certain areas. For Articulated surface drives, the Arneson Surface Drive is the dominant product, thanks to the "universal joint inside a ball joint" configuration patented by Howard Arneson.

Get the drive vendor involved as early as possible in the design process. But remember to carefully evaluate the advice and predictions made by non-technical sales reps. They want to make sales, and are understandably prone to exaggeration at times. Sometimes the most valuable service that the salespeople can provide s a reference to a successful project similar to yours. Naval Architecture has traditionally relied heavily upon improving previous work. And while there may at times be a fine line between plagiarism and "design evolution," it certainly behooves the responsible designer to acquire full knowledge of the current state of the art.

A number of designers and builders have succumbed to the temptation to engineer their own fixed surface drive. Results have usually been less than satisfactory, for a variety of reasons. Probably the most common is placement of the propeller much too close to the transom. Another pitfall is propeller design. Without the support of a propeller or drive vendor experienced with surface propulsion, the propeller performance is an unknown variable. And finally, the self-engineered system is difficult to fine tune. Modifications to propeller and drive geometry in the course of "dialing in" the system can be time consuming and expensive.

Propeller Selection: Surface propellers are usually associated with the stainless steel "cleaver" style common to race boat applications. These propellers have straight trailing edges, razor-sharp leading edges, and sometimes as many as eight blades. Probably because the roots of surface propulsion technology are so firmly imbedded in the race boat world, it's no surprise that the popular perception is that all surface propellers are cleavers. Yet the vast majority of surface propellers being sold today have round-tipped blades, are made of bronze (or NiBrAl), and have only three or four blades. In fact, at first glance there is very little to distinguish them from conventional, fully submerged props.

What distinguishes a surface propeller from an underwater design? The pressure face of the blade is always concave, the leading edge is relatively sharp with a narrow entry angle, and the hub and blade root are built to withstand heavy eccentric and alternating loads. There is major incentive to keep the blade section thin (it's the strength of the steel blades that really gives cleavers the edge at high speeds and loadings). Nearly all successful designs have moderate to heavy trailing edge cupping.

Propeller selection begins with an estimate of required thrust at the design speed. This is usually based on one of several computational methods, but can also be generated from empirical formulas or, if available, trial data from nearly similar vessels. Then a preliminary gear ratio and diameter is chosen, adjusting both until slip and pitch/diameter ratio are optimal and the required thrust is generated. This will generally result in a non-standard reduction ratio, so th remainder of the process involves adjusting diameter and pitch to fit the available drive train hardware. This is, of course, a somewhat simplified description of a "design spiral." Usually the initial design conditions will be modified in the course of the analysis, and there are numerous other considerations such as number of blades, propeller submergence, drive train structural limitations, and vessel trim. Note that unlike propeller selection for a large proportion of conventional applications, diameter remains a variable parameter troughout the entire process.

The drive or propeller vendor is usually eager to perform these calculations for you, and in some cases can supply you with a computer program that will enable you to play with various options on your own.

Problems:

There can be problems with surface propulsion systems, although some of these difficulties stem from other factors not inherently associated with this type of propeller operation.

Vibration: One of the amazing features of surface propulsion is its smoothness at high speed, due mainly to the suppression of cavitation. This is contrary to intuition, and must be experienced to be fully believed. However, some installations have experienced serious vibration problems. In most cases this is due to improper design or alignment of the shafting between the gearbox and drive input shaft. When double universal joint drivelines are required, as is the case with articulated systems, it is especially important to plan the driveline geometry so that operating angles of the two joints are approximately equal and within accepted tolerances. This is because a universal joint does not transmit rotational velocity evenly, causing angular acceleration and deceleration twice with each shaft revolution.

As a general guideline, joint angles should not exceed six degrees per joint, and the difference between the two joint angles should be less than one-half degree. This allows the angular accelerations produced by one joint to be almost exactly compensated by the other joint. (Depending on the orientation of the universal joint yokes, the joint angles can be opposite with driveline flanges parallel, or they can both angle in the same direction for a net total shaft angle change of up to twelve degrees.

The less common vibration problems that are not driveline-related can almost always be solved by using propellers with a larger number of blades, although there is some cost penalty involved.

Backing Performance: Surface propulsion has a reputation for very poor perfomance in reverse. A certain amount of this reputation is based on the fact that until very recently, nearly all surface propeller installations were on very high speed vessels using "cleaver" style propellers. These propellers, due to the thick trailing edges, concave pressure face, and often heavy trailing edge cupping, are notoriously poor performers in reverse. And this is true whether they are used as surface propellers or as cavitating fully-submerged propellers.

However, there is an occasional problem with backing performance of surface propulsion systems, regardless of propeller style. Part of the slipstream of the propellers is directed right into the vessel's transom, with an obvious loss of net astern thrust. Side curtains (hull side extensions aft of the transom) can seriously aggravate this coition. In fact, there has been at least one installation in which the vessel was actually propelled forward when the propellers were turning backwards at certain speeds. The aft overhang and side curtains combined to work like the reversing bucket on a waterjet, except that in this case reverse thrust was being "reversed" to forward thrust!

Fortunately there is an easy fix. The addition of baffle plates between the transom and the propeller that direct the slipstream down and forward (the plates are dr when the vessel is operating ahead at speed) has proved extremely effective. But for the majority of applications, no such hardware is required to provide adequate, although not outstanding, performance in reverse.

Transitional Speeds:

Most planing hull designs, especially moderately low-powered or heavy designs, are subject to problems getting through "hump" speed. High vessel resistance at pre-planing speeds, high propeller slip, and reduced engine torque output at less than full RPM can sometimes combine to make it impossible to reach design speed, even though the vessel may be perfectly capable of operating at design speed once it gets there. The boat that "can't get out of the hole" is a phenomenon that should be quite familiar to many designers and builders. With surface propulsion systems there is an additional factor which may make the situation worse - the propeller is designed to operate with only half of the blade area immersed. But a low speeds, before the transom aerates or "drys out," the propeller must operate fully submerged. Not only is the submerged area doubled, but the top half is operating in very strong wake turbulence right behind the transom. The result is that it takes much more torque to spin the propeller at a given RPM, ad sometimes the engine is not capable of providing the torque necessary to turn the propeller fast enough to get the boat up to the speed which allows the transom to aerate and unload the top half of the propeller.

To reduce this potential problem, various methods of aerating the top half of the propeller have been employed. The Levi drive, for example, directs engine exhaust into the water in front of the propeller. On some installations, passive "aeration pipes" leading from above the static waterline to the forward side of the propeller have been effective. When the lower surface of the aft overhang is below the static waterline, it is sometimes advisable to leave cut-outs through the overhang to let air get to the propellers. With articuated drives, maximum up-trim can sometimes reduce propeller submergence sufficiently to achieve required RPM for take-off power.

Fortunately, these measures are not required for the vast majority of applications. However, designers and builders should be particularly diligent in checking power and thrust margins over the entire speed range, and also be aware of the possibly disastrous consequences of producing a vessel that is seriously overweight.

The Future:

The ability to use large diameters and deep reduction ratios is a capability that is just beginning to be exploited. Surface propellers have long been accepted for racing applications, where minimizing appendage drag and cavitation are the major motivations. In recent years, an increasing number of high-speed yachts and patrol boats have been propelled by surface propellers, and some of these applications have been spectacularly successful. But the use of surface propulsion for relatively heavy and slow vessels is new. A major obstacle to overcome is the first-cost of the large propeller and power transmission equipment capable of handling the higher torques associated with the deep reduction ratios. Life-cycle economics, however, especially for commercial vessels with heavy duty cycles, can be extremely attractive.

We should also look for major evolution in propeller design. The fact that there is no performance penalty for large hub diameter opens the door to new versions of controllable pitch, counter- rotation, and other exotic variations. Propeller blade design is one area where material science may be the controlling technology, as propeller builders experiment with composite blade materials.

But from the builder's point of view, one of the major attractions of surface propulsion is the fact that it does not require any sophisticated or exotic new technology. If anything, the installation of a surface drive is a simplification over conventional shafts and struts. It is simply a re-arrangement of the familiar parts - with significant value added.

Seven Design Rules for Surface-Propelled Vessels

- Make sure the hull form is appropriate for the intended speed range. Semi-planing or low speed planing designs with a high degree of bottom warping (deadrise angle that continues to flatten aft of maximum beam) or keel rocker (curved buttocks aft of maximum beam) will be very poor performers if pushed beyond their intended speeds. Sometimes rocker or warp is included in a hull form because it is believed to improve propulsive efficiency, by increasing the wake fraction (slowing down the water relative to the hull) in way of the conventional propeller location. There will be no benefit if the hull is to be propelled by surface propellers located outside of this wake field. Avoid flow obstructions, such as water pick-ups or trim tabs, directly upstream of any part of the propeller disk.

- Be realistic with weight and center of gravity estimates. Nearly all boats weigh more than the designer and builder would like them to weigh, and this is by far the single most common cause of failure to meet anticipated trial speed. Surface drive vendors will generally be delighted to estimate vessel performance for you, but they need accurate data.

- Use the optimum reduction ratio. It is tempting to save cost by using a shallow reduction ratio and smaller, faster turning, and generally less expensive propellers. At a higher RPM, the same power produces less torque, thereby also reducing the cost of the drive drivelines, and gearbox. This obviates one of the major advantages of surface propulsion, and there are many examples of applications which fail to perform satisfactorily because of insufficient reduction ratio in the interest of first- cost economy.

- Don't neglect trim control. If the design requires trim tabs with underwater propellers, it may require them with surface drives as well. There will be a net vertical force from the surface propellers, depending on a number of parameters including deadrise angle and direction of propeller rotation. Occasionally a vessel that trims well with conventional underwater propellers and no tri tabs is excessively bow-down with surface propellers, and the only satisfactory fix is a center of gravity move. Ask the drive or propeller vendor for assistance in estimating what effect the drive will have on vessel trim. (Trim tabs should not be positioned in front of the propeller disk, however.)

- Don't neglect trim control. If the design requires trim tabs with underwater propellers, it may require them with surface drives as well. There will be a net vertical force from the surface propellers, depending on a number of parameters including deadrise angle and direction of propeller rotation. Occasionally a vessel that trims well with conventional underwater propellers and no tri tabs is excessively bow-down with surface propellers, and the only satisfactory fix is a center of gravity move. Ask the drive or propeller vendor for assistance in estimating what effect the drive will have on vessel trim. (Trim tabs should not be positioned in front of the propeller disk, however.)

- Leave enough space for the engine! Although engine placement and installation is greatly simplified with most surface drives, there is still a certain amount of length required for the drive input shaft, driveline (which usually includes universal and slip joints), and gearbox. There are also some geometric limitations on what a double universal joint driveline can and cannot do. Working with the various vendors early in the design process could avoid a serious problem later on.

- Design the transom to conform to the requirements of the drive. The proper transom angle will eliminate the need for wedges, and in the case of articulated drives, clear space for hydraulic cylinder attachment brackets is essential. Flat transoms allow the most straightforward installations.

- Protect the propeller, but use side curtains sparingly. A surface propeller can be a very substantial hazard to anything or anybody that falls off the stern of a vessel underway. It bears a striking resemblance to a giant food processor! Nearly all recreational designs include an aft cockpit extension, deck extension, or "swim step" that overhangs the propellers, and even military designs use a pipe-and-canvass overhang to protect personnel. Side walls, however, should be used with care. They may have an adverse effect on backing performance.

Paul Kamen is a naval architect with degrees from Webb Institute of Naval Architecture and the University of California at Berkeley. Formerly the Applications Naval Architect for Arneson Marine, he is now an independent consultant specializing in surface propulsion, small craft accident reconstruction and urban ferry system planning.

See Mr. Kamen's Profile on Experts.com.

©Copyright - All Rights Reserved

DO NOT REPRODUCE WITHOUT WRITTEN PERMISSION BY AUTHOR.

Related articles

Follow us