1. INTRODUCTION

In the construction industry, it is largely agreed that overtime work adversely affects labor

productivity. However, there is no universally accepted method for estimating the resulting loss of

productivity, and many of the studies commonly used to estimate such losses have been subject to

criticism by industry experts and the courts.

This article describes a detailed method for estimating productivity losses retrospectively, i.e., after

the hours have been incurred. The proposed method uses the productivity losses from

an MCAA Bulletin published in 2011, in which the MCAA averaged the results from four

well-known overtime studies. Using this method, one applies the MCAA's productivity factors to

the actual hours on a week-by-week, worker-by-worker basis to estimate inefficient hours. Among

its several advantages, the method a relatively time and cost-effective way of providing detailed

results, as it can be used to show the inefficient hours for a given worker or crew, or the

inefficient hours in a given week or timeframe.

The Sections below include a brief introduction to the MCAA Bulletin, a description of the

proposed method including the steps involved with setting up the Excel model, and the advantages

and potential disadvantages of employing this method.

2. THE MCAA BULLETIN

In 2011, the Mechanical Contractors Association of America, Inc. (MCAA) published Bulletin

No. OT1 Revised, titled "How to Estimate the Impacts of Overtime on Labor Productivity."

In its Bulletin, the MCAA did not provide a study based upon new overtime productivity loss

data, but rather it analyzed and summarized the data from four existing studies:1

- "Schedule Overtime Effects on Construction Projects," published by the

Business Roundtable (BRT) in 1980;

- "Overtime and Productivity in Electrical Construction," published by the

National Electrical Contractors Association (NECA) in 1989;

- "Schedule Overtime and Labor Productivity: Quantitative Analysis," published

by Dr. H. Randolph Thomas (Thomas), et al, of Penn State University in 1997;

and

- "Modification Impact Analysis Guide," Publication No. EP 4150-1-3,

published in 1979 by the U.S. Army Corps of Engineers (COE).

Regarding these four studies, the MCAA wrote:

"These studies have been in use in the construction industry for many years and

have been generally accepted as reliable measures of lost productivity due to

unplanned extended overtime. Each has its strengths and weakness, including

criticisms ranging from the use of limited data sources to the withdrawal of

reports from publication. However, the baseline data in any of these studies have

never been proven to be inaccurate. Moreover, the concept that a contractor's

work force becomes less efficient as unplanned extended overtime is worked is

generally recognized and has never been disproved as an underlying fact." 2

The MCAA also cited four cases in which U.S. Courts and Boards acknowledged and/or allowed

the studies to be used as a basis for quantifying productivity losses due to overtime.3

The MCAA then provided a series of charts for each relevant workweek (50 hours per week,

approximately 55 hours per week, 60 hours per week, etc.). Each chart shows the results of the

applicable studies in terms of the Productivity Index as a function of the duration of scheduled

overtime. Between one and four studies were charted, depending upon the workweek.

For example, the chart for the 50-hour workweek includes data from all four studies (BRT,

NECA, Thomas, and COE),4 while the chart for the 84-hour workweek includes data from

NECA's study alone,5 as the other studies did not evaluate the impacts of an 84-hour workweek.

In the balance of its Bulletin, the MCAA provided a table summarizing its results (discussed

below), and explained and gave examples of the prospective application and the retrospective

application of its PIs to estimate productivity loss. While the method proposed in this article is

generally consistent with the simple example of the retrospective application provided in the

Bulletin, it is a far more detailed approach.

3. DESCRIPTION OF THE METHOD

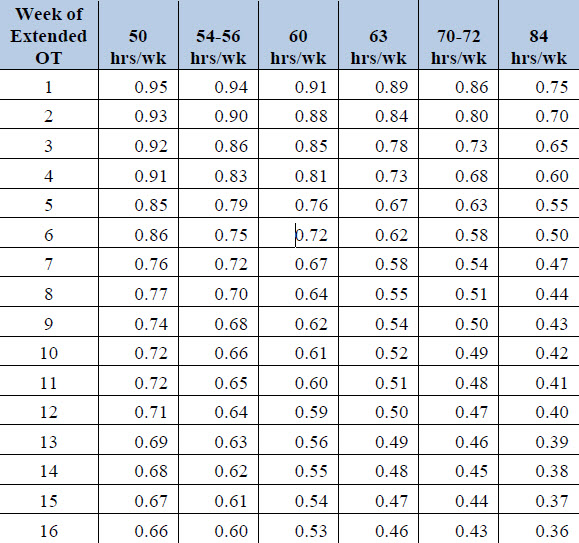

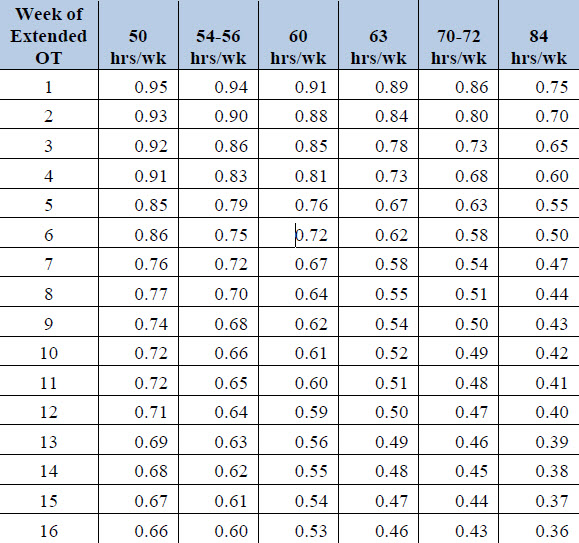

Table 1 below is a recreated version of the MCAA's results table.6 The results indicate that the

Productivity Index (PI),7 and therefore actual worker productivity, decreases both as the weekly

hours increase and as the duration of overtime work is extended. For example, given a 50-hour

workweek, the table indicates that the first week of overtime results in a PI of 0.95, or a 5% loss

of productivity, while the tenth consecutive week of overtime results in a PI of 0.72, or

a 28% loss of productivity. For a 60-hour workweek, the PIs are 0.91 (9% loss) in first week and 0.61 (39% loss) in the tenth week, or more extensive losses than the comparable

50-hour workweeks.

Table 1

Productivity Indices from the MCAA's Bulletin No. OT1 Revised

The method described in this Section applies the PIs (and resulting productivity losses) from the

MCAA's table, Table 1 above, to the actual hours expended by each worker in each week of

a project. Thus, it is a retrospective analysis in which one can quantify not only the total loss

of productive time, but also the lost hours for a given person, in a specific week, or over

a given timeframe.

As a preliminary matter, this author has not, in prior analyses, interpolated between the data

points provided by the MCAA. One might reasonably argue that in the second consecutive week

of overtime, if a worker expended 67 hours, his or her PI may fall between the PI value for the

63-hour workweek (0.84) and the PI value for the 70 to 72-hour workweek (0.80). However,

given that (i) the MCAA does not address such interpolation, and (ii) the studies upon which the

MCAA's values are based do not provide data for say a 67-hour workweek, an analysis that

includes interpolation between data points may (rightly) come under significant criticism.

Therefore, the analysis described below uses ranges that are consistent with the data provided by

the MCAA, e.g.: workweeks between 0 and 49.9 hours are assigned a PI of 1.0 (no productivity

loss); workweeks between 50.0 hours and 53.9 hours use the PIs from the "50 hrs/wk" column;

workweeks between 54.0 hours and 59.9 hours use the PIs from the "54-56 hrs/wk" column; etc.

Table 2 below is excerpted from a larger table in which productivity losses were calculated for

all workers over the entire duration of a project. It shows only John Smith's time over

a six-week period, from the week ending 21 September 2014 (Week 62 of the project) through

the week ending 26 October 2014 (Week 67 of the project).

Table 2

Example Table - Inefficient Hours for One Worker in a Six-Week Period

. . .Continue to read rest of article (PDF).

Long International provides expert claims analysis, dispute resolution, and project management services to the Process Plant Engineering and Construction industry worldwide. Our primary focus is on petroleum refining, petrochemical, chemical, oil and gas production, mining/mineral processing, power, cogeneration, and other process plant and industrial projects. We also have extensive experience in hospital, commercial and industrial building, pipeline, wastewater, highway and transit, heavy civil, microchip manufacturing, and airport projects.

©Copyright - All Rights Reserved

DO NOT REPRODUCE WITHOUT WRITTEN PERMISSION BY AUTHOR.