We are in a global crisis. It’s a matter of life and death. There are shortages of supplies and equipment across the world including acute shortages in America, and yet we are supposed to have a national stockpile, and a coordinated government response. Having 50 governors in 50 different states running in competition with one another for supplies and medical personnel and enforcing different policies is not the optimal way of dealing with the pandemic. Everyone seems to be dealing with supply chain problems – even at the grocery stores where it is impossible to keep paper products and antiseptic wipes in stock.

We know there is plenty of manufacturing capability around the world for consumer goods, PPE, testing equipment, and medical devices such as ventilators. But procurement by thousands of individual hospitals and multiple governmental agencies is uneven and inefficient and we end up with variable pricing, too much inventory in some places, and not enough in others. These may look like supply chain issues on the surface, but they are actually project management issues.

These are not a supply chain issues, but rather a reflection of poor planning and execution. These are project management issues.

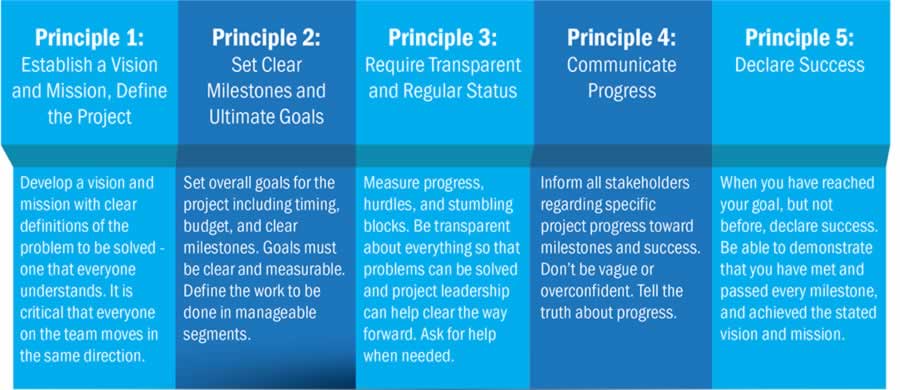

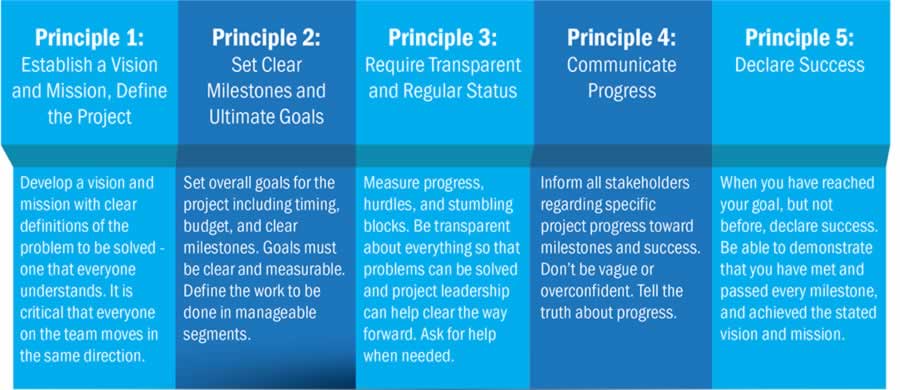

Professional project managers will tell you that successful projects require planning, discipline, milestones, and truthful, regular communications.

When disputes arise in global supply chains, poor project management is often a root cause.

Taking the time to set priorities and develop an end-state vision creates the framework for successful execution. Here are a few principles of project management.

Project management is an essential part of successful supply chains. It is structured and disciplined and a difficult task. It isn’t for the faint of heart. Successful supply chain leaders must also be excellent project managers.

Legal cases often involve poor project management

As an Expert in global supply chains, I work on cases involving sourcing and manufacturing projects, and software implementations that have failed. More often than not, project managers have failed to execute basic project management principles and communication skills. When milestones are missed and hurdles arise, poor project managers typically gloss over these problems, eventually leading to dissatisfaction and conflict. When disputes arise in global supply chains, poor project management is often a root cause.

Rosemary Coates, the Executive Director of the Reshoring Institute and the President of Blue Silk Consulting, is a seasoned executive with an MBA and 25+ years of experience in Chinese Sourcing and Manufacturing, Supply Chain Management, Procurement, Manufacturing and ERP Systems Consulting. Ms. Coates experience spans a broad range of industries including High Technology, Software, Chemicals, Health Care, Consumer Products, Industrial Products, Food Distribution, Transportation, Publishing, Retail, and Oil and Gas. She has testified as an Expert Witness, is a Licensed U.S. Customs Broker, and the author of five books on supply chain.

About the Reshoring Institute: We provide information, research, consulting, and support for companies trying to Reshore manufacturing. This includes topics such as site selection, tax incentives, total cost of ownership, MADE IN USA labeling, marketing, public relations, cost comparison development, and case studies. info@ReshoringInstitute.org.

©Copyright - All Rights Reserved Rosemary Coates & Reshoring Institute 2019

DO NOT REPRODUCE WITHOUT WRITTEN PERMISSION BY AUTHOR.